DLT38-HEAT TREATMENT MACHINE DETAILS

According to the international chain heat treatment standards, as well as the quenching and tempering size of the chain provided by the customer and the related technical requirements, after careful study and discussion by the relevant technical personnel, our company provides the heat treatment equipment scheme for the chain quenching and tempering respectively by using DSP industrial computer controlled double medium frequency power supply. It can be adjusted from the power, frequency and chain speed, so as to adjust the physical characteristics of the chain more conveniently, accurately and reliably, so that it can meet the requirements of the high grade chain. The details are as follows:

1. Requirements for main technical parameters

1.1 Specification and size of quenching and tempering chain:

To meet the requirements of Φ18×64mm, 22×86mm chain quenching and tempering heat treatment;

To meet the requirements of Φ26×92mm, N30 ×108mm, N34 ×126mm, N38 ×137mm chain quenching and tempering heat treatment;

1.2 The quenching temperature of the chain is 900℃ ~ 1050℃ (adjustable by power and chain speed);

Chain tempering temperature 200℃ ~ 600℃ (adjustable by power and chain speed);

1.3 The power supply adopted is IGPSZ intelligent double medium frequency power supply. The quenching power supply and tempering power supply are independent output, and the power and frequency can be controlled independently. DSP industrial computer + touch screen interface is used to control the control mode, and imported IGBT inverter is used for the inverter bridge.

1.4 The power and frequency of the quenching and tempering power supply of the chain can be adjusted independently, and the frequency of the power supply automatically follows the constant power factor control, power factor > 0.95;

1.5 The whole system adopts industrial computer for centralized operation and control, and has convenient and beautiful man-machine interaction interface;

1.6 The pollution of equipment harmonics to the power grid meets the requirements of the national standard GB/T14549-93 "Harmonics of Power Quality Public Grid";

1.7 Medium-frequency power cabinet and capacitor cabinet adopt closed cycle cooling of purified water; The inductor and quenching spray water are cooled by pool water.

V. Product overview

Intelligent IGPSZ medium frequency power supply device is used in casting, heat treatment and motor welding industries such as melting, diathermic, quenching, tempering, sintering, welding, heating, etc. The device is controlled by a new generation of digital processing chip (DSP), which has the characteristics of automatic frequency tracking, fast start speed and reliable fault diagnosis.

The system adopts the all-solid medium frequency induction heating power supply developed by the new high-power power electronic device IGBT, which is highly efficient and energy saving. It has the following characteristics:

• High efficiency and energy saving, the overall efficiency is 93%;

• Electronic control and monitoring protection system is completely reliable;

• Frequent startup, safe and reliable, 100% success rate of startup;

• The output can be controlled by constant power, constant voltage and constant current;

• Wide range of load adaptation, easy adjustment;

• The main components adopt international famous brands, low maintenance cost;

• Adopt water circulation cooling, good cooling effect;

• Simple operation and easy maintenance.

Six, the principle of the intermediate frequency power supply

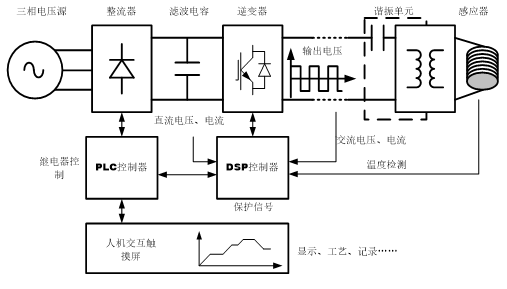

The main circuit of the system is mainly composed of four parts: three-phase uncontrollable rectifier unit, single-phase full-bridge inverter unit, transformer transmission unit and resonant induction heating part.

The system control principle diagram is as follows:

6.1 IGPSZ intermediate frequency power main loop

The main loop rectifier of IGPSZ intermediate frequency power supply produced by our company is composed of three-phase full-wave rectifier unit with water-cooled diodes produced by Taiki Semiconductor. The IGPSZ intermediate frequency power inverter bridge is composed of IGBT module produced by Infineon and IGBT special driver produced by Kangsay, which has stable and reliable operation, high efficiency and high working frequency.

A. Three-phase full-wave rectifier unit

Three - phase full - bridge rectifier unit is a rectifier circuit composed of six diodes. Because the whole circuit is uncontrollable rectification mode, there will be no chopper modulation for three-phase AC sine wave, so there will be no interference, distortion and harmonic interference to the power grid.

B. Inverter unit

Inverter unit is composed of German Infineon IGBT module. Insulated Gate Bipolar Transistor IGBT(Insulated Gate Bipolar Transistor) It is composed of BJT(bipolar triode) and MOS(insulated gate type field effect tube). It has the advantages of high input impedance of MOSFET and low on-voltage drop of GTR. GTR has lower saturation voltage, higher current-carrying density, but higher driving current. MOSFET driving power is very small, switching speed is fast, but the conduction voltage drop is large, the current-carrying density is small. IGBT combines the advantages of the above two devices, low driving power and low saturation voltage. Suitable for converter systems with DC voltage of 600V and above, such as AC motor, frequency converter, switching power supply, lighting circuit, traction drive and other fields.

6.2 IGPSZ IF power supply power and power factor control

The basic composition of intermediate frequency heating power supply is a simple LC series circuit. When the power frequency of the circuit works at the natural resonance point of the circuit, the system presents a pure resistance characteristic. The input power of the power supply can be maximized into the magnetic field energy stored by the induction coil. This system controlled by DSP real-time tracking the maximum power factor, the power always work in the natural resonance point, power factor can reach more than 98%, at this time, the system output power - the current largest, so which can make the current rapid response, rapid temperature adjustment, greatly reduce the preheating time, but also to maximize efficiency, save a lot of energy. When the power supply frequency is adjusted to the natural resonance point of the circuit, the output current of the power supply depends entirely on the output voltage of the inverter. By controlling the conduction ratio of the inverter unit, the output voltage of the inverter is controlled, and the regulation of input/output power is realized.

6.3 Main controller

The main controller adopts Siemens S7-200 PLC, which is mainly used for the communication between DSP controller and human-computer interaction interface, as well as the processing of the whole system motion quantity, analog quantity and protection signal. The CPU of the PLC is 224XP, integrated 14 input/output 24 digital I/O points, 2 input /1 output a total of 3 analog I/O points, can connect 7 expansion modules, the maximum expansion value to 168 digital I/O points or 38 analog I/O points. PLC has a strong anti-interference and stability, the controller's analog output and PID control can fully meet the needs of the control system.

6.4 DSP Controller

The 32-bit DSP chip of TI Corporation in the United States is used to regulate the voltage of the high frequency power supply by controlling the conduction ratio of the inverter bridge, and the frequency of the power supply is adjusted by controlling the output frequency of the IGBT inverter bridge. The system can realize automatic frequency tracking, set a variety of protection, to ensure the safety of the system, such as system failure, you can carry out sound and light alarm, remind the operator to deal with in time.

Compared with ordinary single-chip microcomputer, DSP has its unique advantages, for example, the single-instruction cycle of 51-series single-chip microcomputer is 2_S; The 80C196KC operation instruction cycle is 125ns. Due to the limitation of speed, it is difficult to realize the perfect output of intermediate frequency power SPWM by using the power supply controlled by single chip microcomputer. TMS320F2808 is designed for motor control, digital power supply, automotive control and advanced sensing applications. It features onboard 128KB flash memory and up to 100MIPS (10ns) 32-bit DSP performance, supports high sampling rate, reduces cycle delay, and has powerful peripheral functions. Faster transient response can be achieved by positioning PWM signal edge with 150PS accuracy or 16bit accuracy. TMS320F2808 has 12 bit /16 pass analog-to-digital converter (ADC), 16 unique PWM channels, key communication interfaces including a variety of CAN, 12C, UART and SPI ports, CAN reduce the cost, while making the system has a strong programmable, easier to update and upgrade.

6.5 HMI touch screen

The purpose of man-machine dialogue is to control the operation of the equipment through the use of man-machine communication terminal, operation control software, so that the entire operation process of the device is simple and clear, the device automatically and intelligently run. Human-machine interaction using touch screen control, stable, reliable, long life, very suitable for the harsh electromagnetic environment of the industrial site

11、CUSTOMER PHOTO